Are you tired of those pesky bubbles ruining your vinyl wrapping projects? You’re not alone.

Many people find themselves frustrated with bubbles that seem to pop up at the worst times, turning a sleek finish into a bumpy mess. But what if you could transform your vinyl wrapping experience from a bubble-laden struggle to a smooth, professional-looking finish every time?

In this guide on how to ensure a bubble-free finish with vinyl wrapping, you’ll discover proven techniques and helpful tools that make all the difference. Imagine the satisfaction of achieving that flawless, smooth look—completely free from imperfections and air pockets.

Ready to elevate your vinyl game and impress with perfection? Let’s dive in and uncover the secrets to a seamless, bubble-free wrap.

Preparation For Vinyl Wrapping

Preparing for vinyl wrapping is crucial. It prevents bubbles and ensures a smooth finish. Proper preparation makes the wrapping process easier and yields better results. Let’s explore the essential steps for a flawless wrap.

Surface Cleaning

A clean surface is vital. Dirt and dust create bubbles under vinyl. Use a gentle cleanser to wipe the area. Ensure all residue is removed. Pay attention to corners and edges. These spots often trap grime. A microfiber cloth works best for this task.

Temperature Considerations

Temperature affects vinyl adhesion. Ensure the environment is warm. Cold surfaces can cause bubbling. The ideal temperature is around 70°F. Avoid direct sunlight during application. Sunlight heats the surface unevenly. It may cause stretching or bubbling.

Material Selection

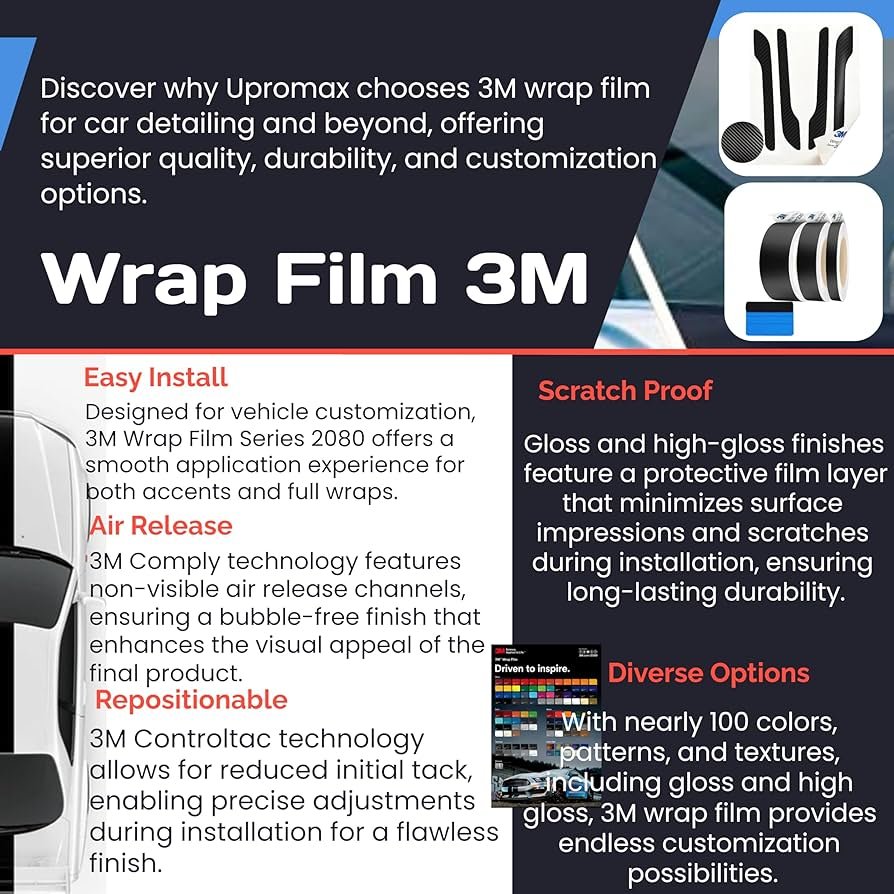

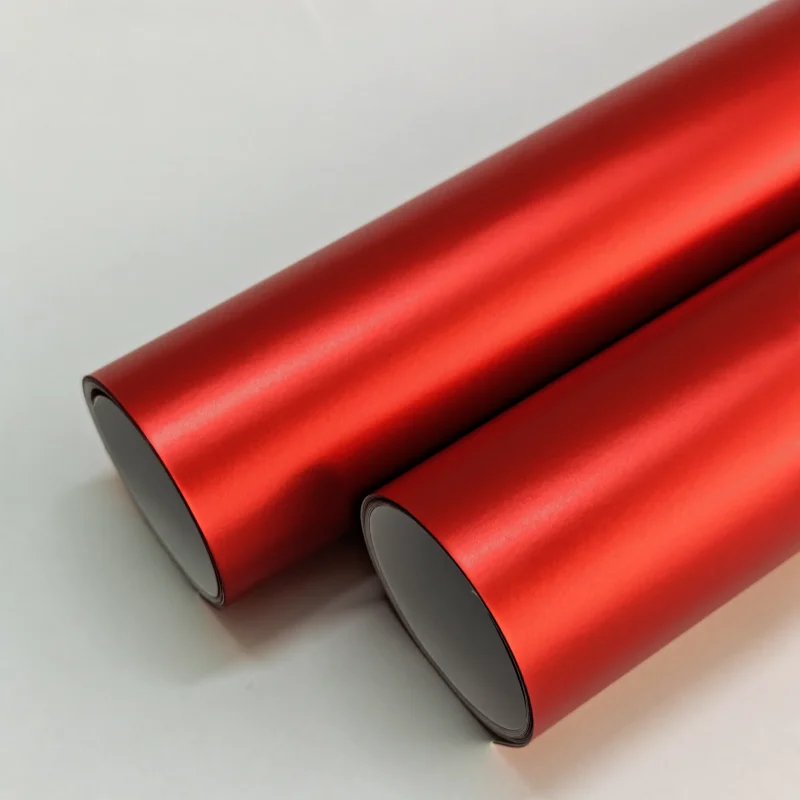

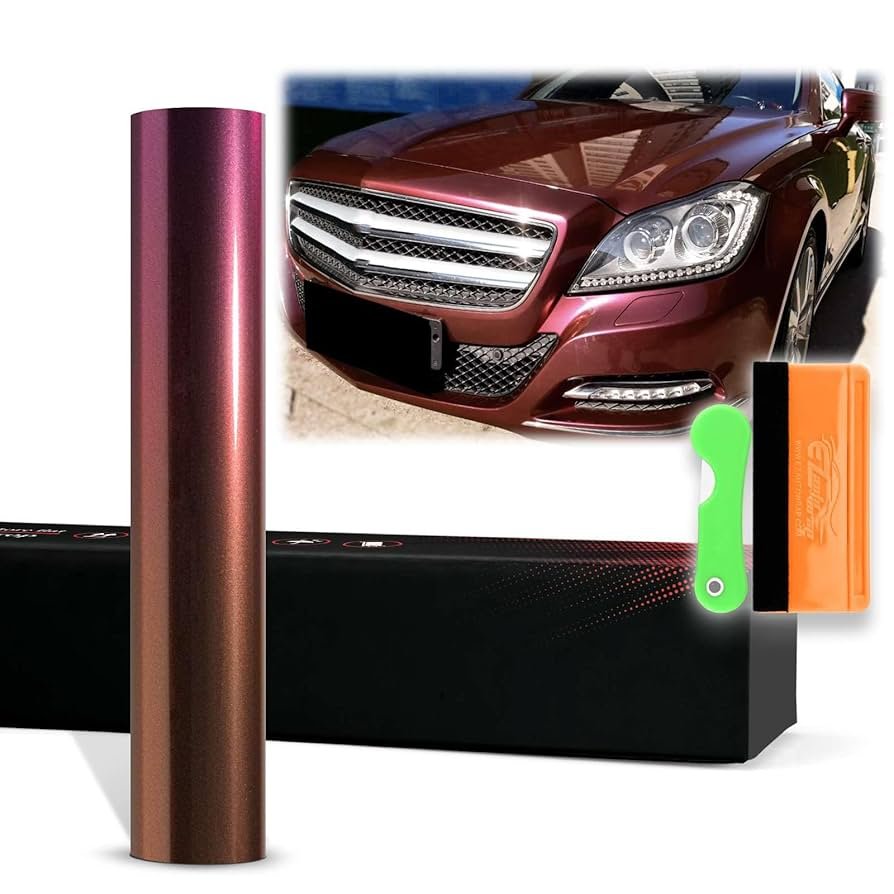

Choose high-quality vinyl. Cheap materials often bubble easily. Test the vinyl on a small area first. Ensure it adheres well. Consider the vinyl’s thickness. Thicker vinyl is more durable. It reduces the chances of bubbles forming.

You may read also: What is Vinyl Floor Wrapping And the Benefits: Ultimate Guide

Tools For A Smooth Finish

Achieving a smooth finish with vinyl wrapping requires specific tools. Use a squeegee to remove air bubbles. Heat guns help ensure a tight fit around curves. These tools make the application process seamless.

Wrapping a car in vinyl can be a transformative experience. The process can turn an ordinary vehicle into a stunning masterpiece. However, achieving that seamless, bubble-free finish isn’t just about the technique; it’s also about having the right tools at your disposal. Let’s delve into the essentials and some advanced tools that can make your vinyl wrapping project a smooth success.

Essential Equipment

To start your vinyl wrapping journey, you’ll need some basic tools. A high-quality squeegee is a must-have. It helps you smooth out the vinyl and remove any air bubbles. Opt for one with a felt edge to prevent scratches. A heat gun is another crucial tool. It allows you to stretch and mold the vinyl, especially around curves and edges. Remember to keep it at a safe distance to avoid overheating the material. A precision knife or cutter is also essential. This tool ensures clean cuts and trims around edges and corners. Make sure it’s sharp for best results.

Advanced Tools For Professionals

To level up your vinyl wrapping skills, consider using professional-grade tools. A laser thermometer helps maintain the ideal temperature, while a wrap glove ensures smooth, scratch-free application. Vinyl wrap magnets hold material in place for better control, and cutting tape lets you trim without risking paint damage. Each tool plays a key role in achieving a flawless, bubble-free finish.

Application Techniques

Achieve a smooth vinyl wrap by cleaning surfaces thoroughly before application. Use a squeegee to remove air pockets. Gently heat the vinyl to ensure it adheres evenly.

Applying vinyl wrap to a car or any surface can be both an art and a science. Ensuring a bubble-free finish involves mastering specific techniques. These techniques are critical for achieving that flawless look. Let’s dive into some practical application methods that will help you perfect your vinyl wrapping skills.

Starting Points

When beginning your vinyl wrap project, selecting the right starting point is essential. Start from the center of the surface to allow the wrap to stretch evenly to the edges. This approach minimizes tension and reduces the likelihood of air bubbles forming. Consider your work environment. A clean, dust-free space is crucial. Dust can easily get trapped under the vinyl, causing imperfections. Take the time to clean the surface thoroughly before starting.

Avoiding Stretching

Stretching the vinyl excessively can lead to bubbles and warping. Apply gentle, even pressure as you smooth the vinyl out. A friend once rushed a wrap job and ended up with unsightly creases due to over-stretching. Use a heat gun to soften the vinyl slightly. This makes it pliable, allowing you to mold it without stretching. Be cautious with heat to avoid damaging the material.

Managing Curves And Contours

Curves and contours can be the trickiest areas to wrap without bubbles. Use a squeegee to apply the wrap smoothly around these areas. By working slowly and steadily, you can ensure the wrap adheres perfectly. For complex curves, consider making small relief cuts. This helps the vinyl conform without bunching or creasing. Remember, patience is key when dealing with intricate surfaces. Are you ready to transform your vehicle with a bubble-free vinyl wrap? These techniques are your stepping stones to success. Embrace the process and watch your skills improve with each project.

Bubble Prevention Strategies

Achieve a smooth vinyl wrap by cleaning surfaces meticulously. Use a squeegee to press out air. Apply heat gently. This ensures a bubble-free finish.

Vinyl wrapping can transform any surface into a sleek, modern marvel. However, nothing disrupts this smooth finish more than pesky bubbles. Bubble prevention is crucial for achieving that flawless, professional look. You might think it’s a daunting task, but with the right strategies, you can ensure a bubble-free finish every time. Let’s dive into some effective bubble prevention techniques that will help you wrap like a pro.

Air Release Techniques

Air release channels in vinyl are your best friend. They allow trapped air to escape, reducing the chance of bubbles. Always start by smoothing the vinyl from the center outwards. This way, any trapped air can naturally find its way to the edges. Have you ever felt the frustration of a stubborn bubble? Using a small pin to gently release air can be a lifesaver. Just be sure to smooth the vinyl afterward to ensure a seamless finish. Remember, patience is key here.

Using Heat For Bubble Removal

Heat can be a game-changer for bubble removal. A heat gun or even a hairdryer can help make the vinyl more pliable. This flexibility allows you to easily press out any bubbles. Be cautious with the temperature, though. Excessive heat can damage the vinyl. Keep the heat source moving to prevent burning or warping the material. It’s all about finding that sweet spot.

Proper Pressure Application

The right amount of pressure is essential. Use a squeegee to apply consistent pressure across the vinyl. Begin with light strokes and gradually increase pressure as needed. Are you pressing too hard? Too much force can stretch or tear the vinyl, leading to more issues than just bubbles. Aim for firm but gentle strokes to maintain the integrity of the wrap. It’s like giving the vinyl a gentle massage, rather than a hard push. These strategies are not just about technique; they are about understanding the material you’re working with. Have you discovered any tricks in your own vinyl wrapping journey? Share them in the comments below, and let’s wrap it up together!

Post-application Care

After applying vinyl wrap, care is essential for a perfect finish. Post-application care ensures the wrap remains bubble-free and intact. Proper attention prolongs the lifespan of the vinyl. It also enhances its appearance.

Inspection And Corrections

Start by examining the entire wrapped surface. Look for any bubbles or imperfections. Use a soft squeegee to smooth out small bubbles. For stubborn bubbles, a pin can help release trapped air. Gently pierce the bubble and press the air out. Always work slowly to avoid damaging the vinyl.

Maintenance Tips

Regular cleaning keeps the vinyl wrap fresh. Use a mild detergent and a soft cloth. Avoid harsh chemicals that can damage the wrap. Hand wash the wrapped areas to prevent peeling. Be cautious when using pressure washers; keep the nozzle at a safe distance. Inspect the edges regularly for signs of lifting or peeling. Address issues quickly to prevent further damage.

Common Mistakes To Avoid

Achieving a flawless finish with vinyl wrapping can be challenging. Many make common mistakes that lead to bubbles. Being aware of these pitfalls can save time and effort. Let’s delve into these common errors to ensure a smooth wrap every time.

Ignoring Temperature

Temperature plays a crucial role in vinyl wrapping. High temperatures can make the vinyl stretch too much. Cold temperatures might make it brittle and hard to work with. Always check the recommended temperature range on the vinyl packaging. Working in the right conditions prevents bubbles and ensures a smooth finish.

Rushing The Process

Patience is key in vinyl wrapping. Rushing can cause mistakes and imperfections. Take time to align and apply the vinyl carefully. Use a squeegee to smooth out bubbles slowly. Haste often results in creases and unwanted air pockets. A careful approach leads to better results.

Underestimating Surface Preparation

Surface preparation is vital for a bubble-free wrap. Dirt, dust, and grease can prevent the vinyl from sticking properly. Clean the surface thoroughly before starting. Use alcohol-based cleaners for best results. Skipping this step can lead to adhesion problems and bubbles. Proper preparation is half the battle won.

Frequently Asked Questions

How Do You Avoid Bubbles In Vinyl Wrapping?

To avoid bubbles, start with a clean surface free of dirt and oils. Use a squeegee to apply even pressure while installing. Work slowly, from one edge to the other. Use heat to soften the vinyl and smooth out any imperfections.

A pin can help release trapped air.

What Tools Help Achieve A Smooth Vinyl Wrap?

Essential tools include a squeegee, heat gun, and a pin. A squeegee ensures even pressure and smooth application. A heat gun softens the vinyl for better conformity. A pin is useful for releasing trapped air bubbles. Having a clean microfiber cloth is also beneficial for final touches.

Can Temperature Affect Vinyl Wrap Application?

Yes, temperature plays a crucial role. Cold temperatures make vinyl stiff, leading to bubbles and creases. Warm temperatures help the vinyl adhere smoothly to surfaces. Ideally, apply vinyl wrap in temperatures between 70°F and 80°F. Always use a heat gun to ensure perfect adhesion and flexibility.

How Long Does Vinyl Wrapping Take?

Vinyl wrapping time varies based on surface size and complexity. Simple surfaces might take a few hours, while complex shapes can take longer. Preparation is key; clean and dry the surface thoroughly. Expect a full vehicle wrap to take one to three days, depending on experience.

Conclusion

Achieving a bubble-free vinyl wrap is not difficult. Start with a clean surface. Use a squeegee to smooth out bubbles. Work slowly and carefully. Don’t rush. Temperature matters; ensure it’s not too hot or cold. Practice makes perfect. Experience helps avoid common mistakes.

Use quality materials for best results. Follow these tips and your vinyl wrap will look professional. No bubbles, just a smooth finish. Enjoy your new, sleek look. Keep your vinyl wrap looking great with regular care. Your vehicle will turn heads with its flawless appearance.

Happy wrapping!